Transparent resist for the overcoat protection of LCD color filter (Overcoat)

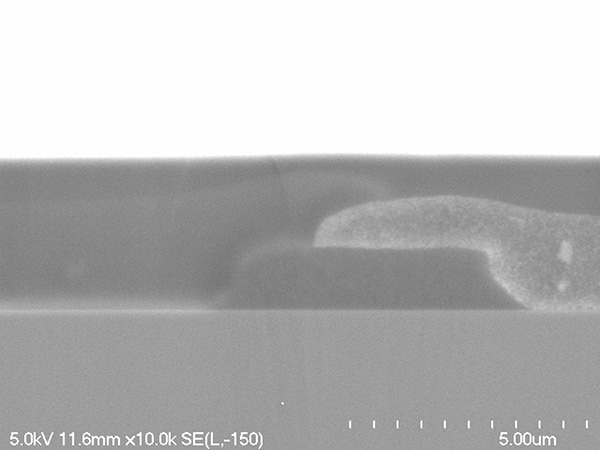

Our transparent resists for the protective film are excellent in heat resistance, transparency and flatness. They can contribute to the improvement of LCD display performance and reliability. We offer UV curable (negative) resists when patterning such as contact holes is required, and thermal curable resists when there is no exposure process and the film is formed only by heating.

| Items | Unit | V-259PHA series |

V-259EH series |

||

| Curing type | - | UV curable |

Thermal curable |

||

| Applications | - | Color filter for large and small/medium-area LCD |

|||

| (RGB) | (RGB W) |

(RGB) | (RGB W) |

||

| Viscosity | mPa•s | 2~10 | 2~3 | ||

| Solid content |

% | 10~30 | 10~20 | ||

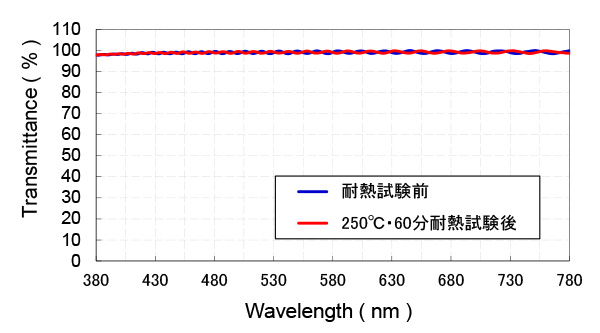

| Transmittance (400nm) |

% | 95.0< | |||

| Heat resistance (Transmittance) *1 |

% | 95.0< | |||

| Flatness *2 |

μm | <0.2 (1.5 μm t) |

<0.3 (1.5 μm t) |

<0.1 (1.0 μm t) |

<0.2 (1.5 μm t) |

| Volume resistivity | Ω•cm | 1014< | |||

| PCT adhesion | - | 5B | |||

| Hardness | - | 2~4H | |||

| Voltage Holding Ratio*3 | % | 99 | |||

| Recommend Conditions | - | VCD:≦100Pa HP:90℃, 1min Exposure:50~100mJ/cm² (Proximity exposure apparatus) Development:KOH or Na₂CO₃ Developer: 23~26℃, 40~60sec Oven:230℃, 30min |

VCD:≦100Pa HP:90℃, 2min Oven:230℃, 30min |

||

*1 250℃, 60min

*2 Max. gap, RGB thickness <2.5μm, t: thickness

*3 Naga-type Liquid Crystal, 25℃, 5V, 30/60Hz